PERFORMANCE

From 18 to 60 packages per minute- packaging of sizes up to ¼ pallet. In the BIG version, the machine can process trays for the packaging of sizes up to 1/2 pallet (it requires the necessary additional module).

ADVANTAGES

TECHNICAL DETAILS

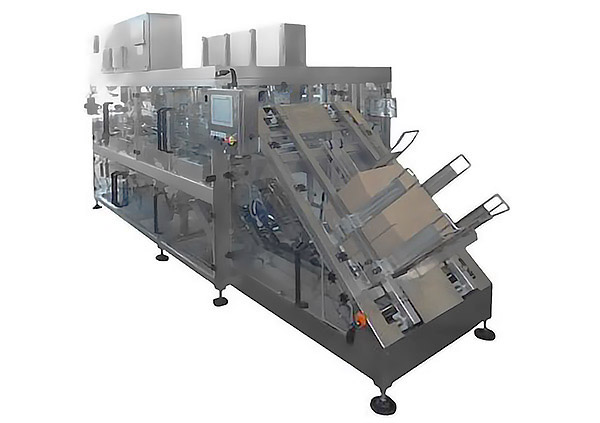

Cardboard packer with painted steel structure (possible option: stainless steel) for the packaging of various type of products in open trays with linear, 90° and 180° infeed in single lane even more compact version for a greater reduction of overall dimensions .

Main machine features:

- Painted steel machine bearing structure (possible option: stainless steel)

- Pneumatic product separator to enable a smooth product channelling

- Minimum accumulation photocell control for each channel

- Pneumatic product separation

- Continuous motion bar conveyor, synchronised with the machine that leads the product directly to the die cut

- Motorised die cut pick-up from the machine

- Tray formation unit around the product with hot-melt group

- Easy, fast size changes

- Main automatic controls with alarm and machine stop signals for:

– “Minimum die cut storage accumulation”

– “No die cut pick-up”

– “No die cut under product”

– “Product overturned or missing” - Electrical cabinet on the machine

- Control panel with “touch-screen”colour display

EXAMPLES OF PROCESSES

ADDITIONAL MODULES

- Module for multi layer stacking

- Module for vertical interlayer insertion

- Module for 1/4 pallet tray and Module for 1/2 pallet tray

- Module for upper overflap application on trays

- Module for cover application on trays

- Module for wrap-around box formation and closing

- Module for staggered product arrangement (QUINCONCE POSITIONING)

OPTIONAL

SEMI AUTOMATIC FORMAT CHANGE

This machine automatically adjusts wrap-around cardboard formation unit based on width, length, and height of the package.

It also automatically adjusts the width and the uprising of the cardboard itself.

The other adjustments remain manual (cardboard storage, product input guides, etc.).

Advantages: very reduced format change times and with minimum manual intervention by the operator.

AUTOMATIC FORMAT CHANGE

All machine adjustments are carried out automatically in changing from one format to another.

Advantages: very reduced format change times and without manual intervention by the operator.